Casting Capacity

The advanced casting process - low temperature wax Silica Sol precision casting process and phenolic resin sand process are adopted. The materials include carbon steel, austenitic stainless steel, wear-resistant cast iron, bidirectional stainless steel, etc., which can meet the production of castings with different requirements.

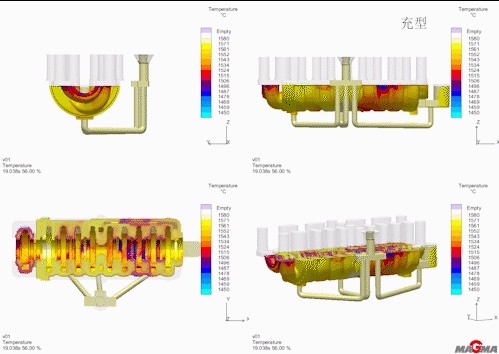

Equipped with the latest 3D printing equipment, magma casting solidification analysis software, automatic modelling assembly line, abb manipulator and other high-end equipment, it not only ensures the high quality of castings, but also provides strong support for the company's R & D and rapid response to the user's delivery date.

Equipped with the latest 3D printing equipment, magma casting solidification analysis software, automatic modelling assembly line, abb manipulator and other high-end equipment, it not only ensures the high quality of castings, but also provides strong support for the company's R & D and rapid response to the user's delivery date.

ABB Manipulator ABB Manipulator |

3D Sand Printer 3D Sand Printer |

Modeling Pipeline Modeling Pipeline |

Magma Simulation Software Magma Simulation Software |

Process Flow Of Precision Casting

Wax treatment

Wax injection

Assembly welding

Hanging sand

Dry

Dewaxing

Mold shell

Melting and pouring

Guide vane / impeller

Wax treatment

Wax injection

Assembly welding

Hanging sand

Dry

Dewaxing

Mold shell

Melting and pouring

Guide vane / impeller

Process Flow Of Sand Casting

Model

Modelling

Closed box

Melting

Furnace front analysis

Pouring

Subsequent treatment

PT/MT/UT/Endoscopy

Turbine casing / pump body

Model

Modelling

Closed box

Melting

Furnace front analysis

Pouring

Subsequent treatment

PT/MT/UT/Endoscopy

Turbine casing / pump body